Cal Maritime Team Wins First Place in U.S. Department of Energy Collegiate Wind Competition

The U.S. Department of Energy (DOE) estimates that wind generation could double by 2020 and double again by 2030. As the number of wind-energy-related jobs increases, the U.S. will need qualified candidates to fill positions at all levels. To help facilitate this process, in 2014, the DOE and the National Renewable Energy Laboratory (NREL) co-created the Collegiate Wind Competition.

The goal of the competition is to challenge "interdisciplinary teams of undergraduate students from a variety of programs to offer a unique solution to a complex wind energy project, providing each student with real-world experience as they prepare to enter the wind industry workforce. The students are challenged to design a wind turbine based on market research, develop a business plan to market the product, build and test the turbine against set requirements, and demonstrate knowledge of siting constraints and location challenges for product installation."

This year, 12 teams from across the continental U.S. and Puerto Rico entered the competition, including California State University Maritime Academy (Cal Maritime), one of only seven degree-granting maritime academies in the U.S. and the only one on the West Coast. The Cal Maritime team won first place for their innovative turbine design, siting plan, and business proposal. The team had the highest cumulative scores in all categories and was named overall winner by a panel of wind industry experts.

We're proud that the Bantam Tools Desktop PCB Milling Machine was an integral tool in the development of their turbine.

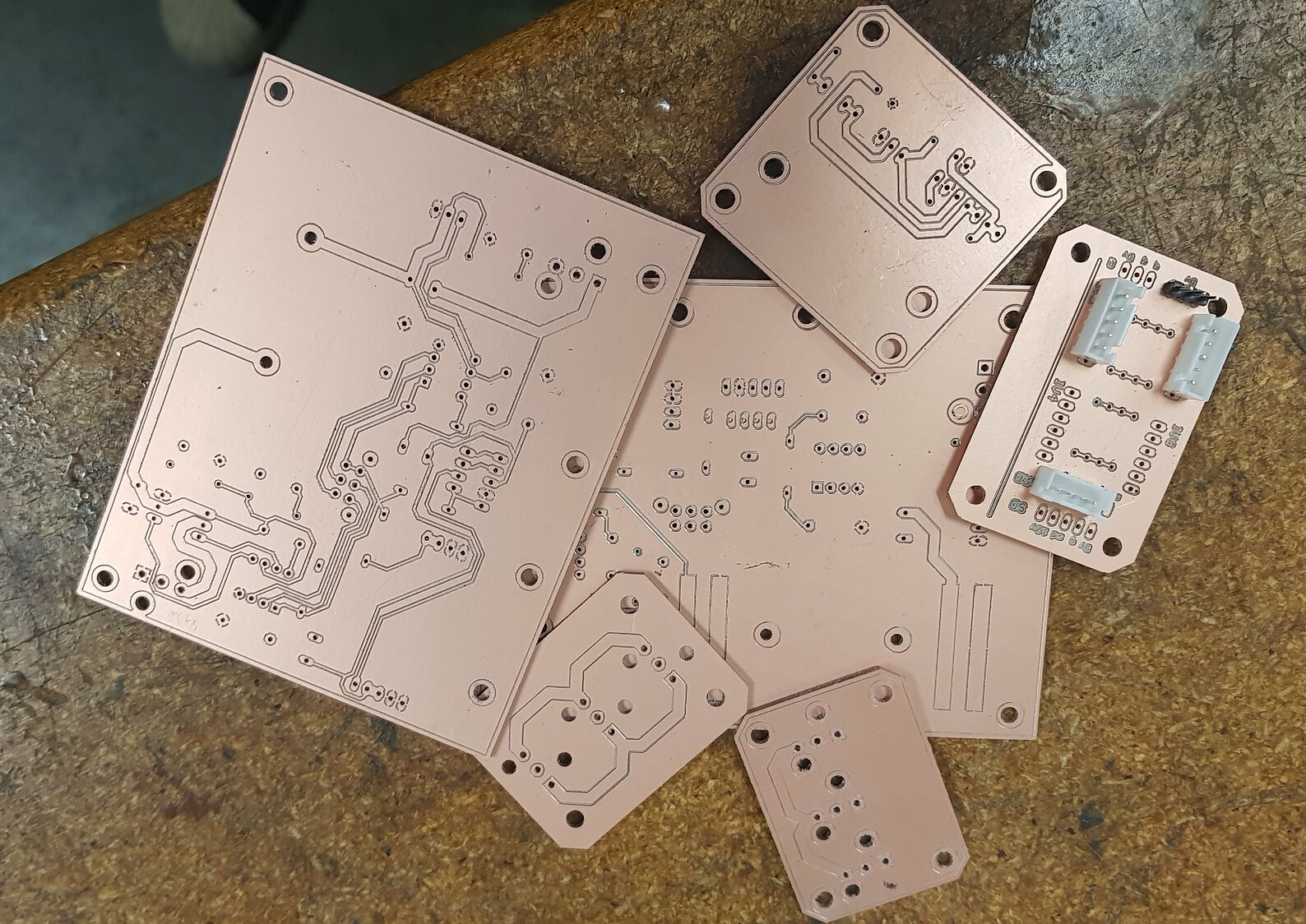

Three years ago, Cal Maritime acquired their first Bantam Tools Desktop PCB Milling Machine, integrating it into a number of courses starting with ET 370 Electronics and ET 350 Electro-Mechanical Machinery, as well as using it for their entry into the Collegiate Wind Competition. Last year, we spoke with Associate Professor Dr. Evan Chang-Siu, who shared that the Bantam Tools Desktop PCB Milling Machine (previously called Othermill) had "allowed the students to create much more reliable, compact, and professional-looking circuit boards." He also noted the superior workflow efficiency of our software, making it accessible to students of all levels.

The Bantam Tools Desktop PCB Milling Machine was originally created with educational usesin mind, so naturally we're thrilled that our precise, reliable, and easy-to-use tool was able to help the Cal Maritime team iterate their way into first place!

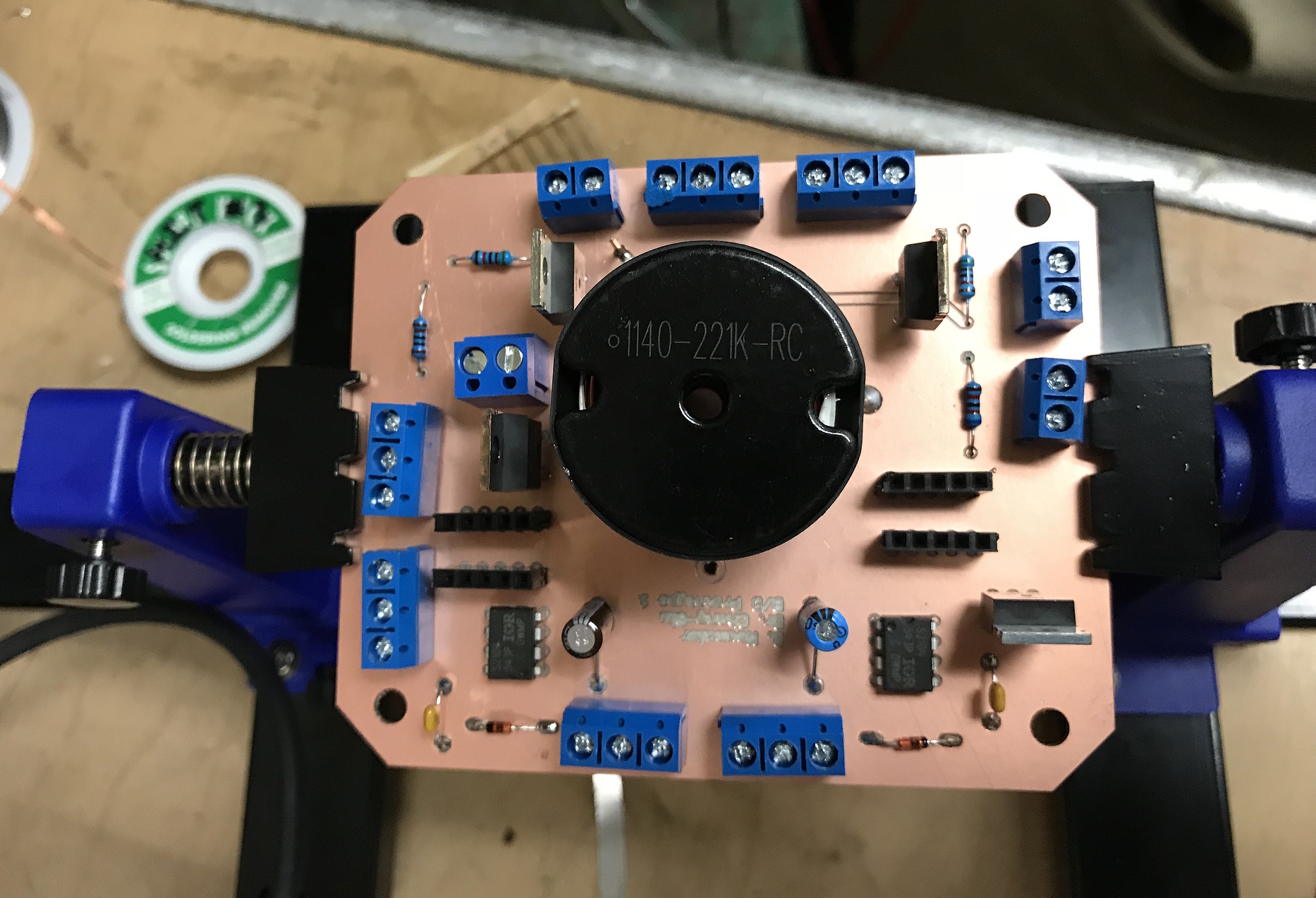

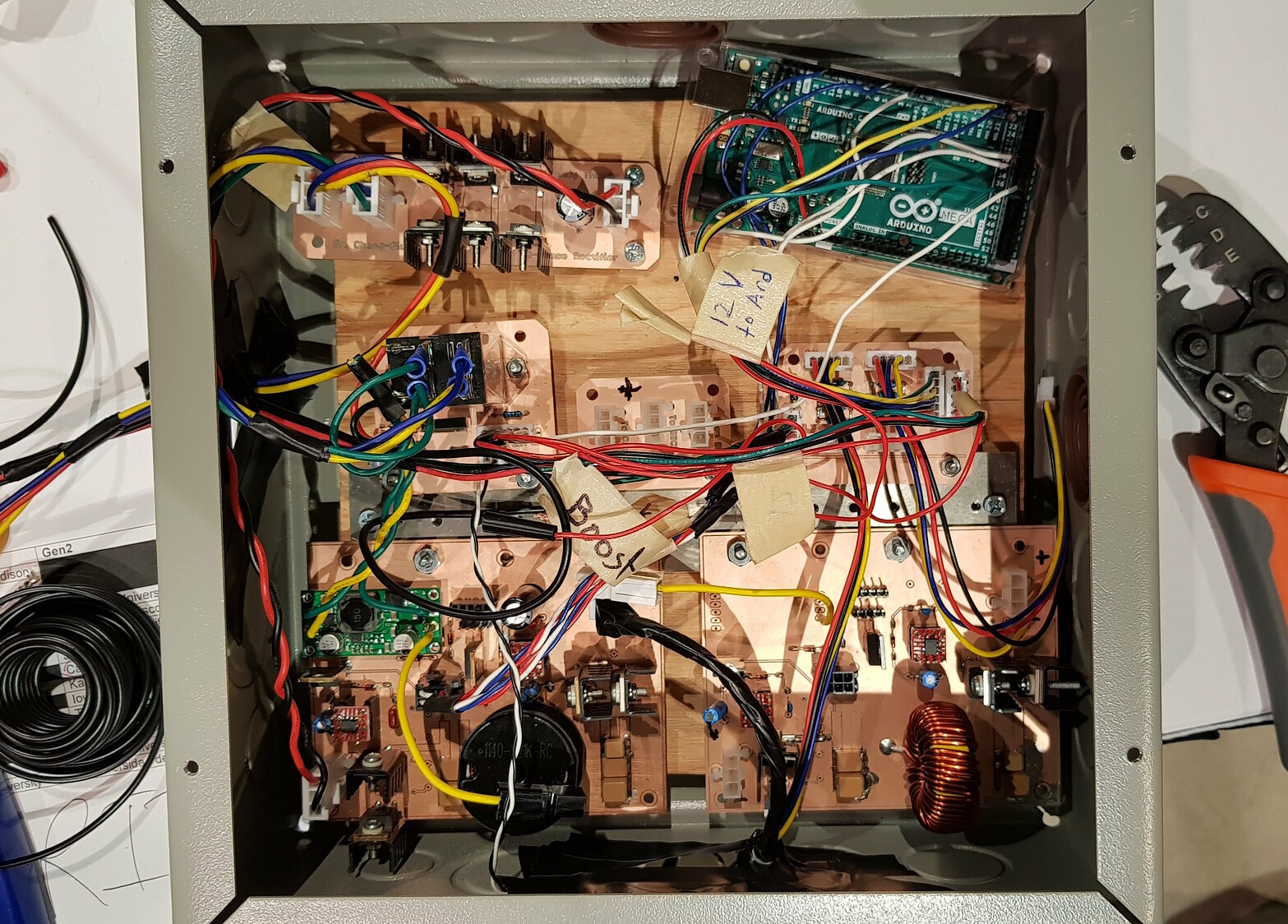

From the team's final project report, here are details of their turbine's power electronics:

The turbine’s electrical system consists of 3 major components; a generator, rectifier, DC/DC converter of buck boost architecture and a load. The active component is the buck-boost converter (BBC) which applies a gain (G) to the input voltage (Vin) from the turbine to the load. An inverse gain (1/G) is applied to the input current (Iin) from the generator. Since the load voltage remains relatively constant at 6 volts, influencing a voltage gain with the BBC has the effect of changing Vin and thus the rotor speed of the turbine. An Arduino M0 microcontroller is used to automate the BBC gain for the purpose of tracking max power points and regulating power when necessary.

The entire Cal Maritime team is shown at the top of this post. They are (clockwise from left): Dr. Evan Chang-Siu (Faculty Advisor), Dylan Sanchez, Adam Olm, Zachary Thomas, Ryan Storz (Faculty Advisor), Lydia Thanh, Dr. Tom Nordenholz (Principle Investigator), Stefano Maffei, Quentin Williams, Matthew Leli, Joseph Phillips, Jonah Grier, Bartlett Tamarro, Daniel Neumaier, and Darlene Conolly. Not shown are Dr. Tony Lewis (Faculty Advisor) and Dr. Ryan Dudley (Faculty Advisor).

Congratulations to Cal Maritime on this great honor! We're proud that our Bantam Tools Desktop PCB Milling Machine was instrumental in this project's development and iteration. We can't wait to see what incredible change these bright minds affect in the future!