Chasin Spin on Milling Custom PCBs

It's safe to say that most folks seek shelter when faced with extreme adverse weather, but that's not the case for ChasinSpin. The quest for capturing storm images doesn't come neatly wrapped in a box. Instead it's driven by innovation, and ChasinSpin employs the Bantam Tools Desktop PCB Milling Machine to create custom PCBs for his custom-built tools. Intrigued, we caught up with ChasinSpin to learn more.

1. Tell us about yourself. What's your background?

Software, firmware and hardware development, Masters of Science.

2. How did you get into storm chasing?

Always had a passion for severe weather, lightning, large hail, tornadoes.

3. What drives you to do what you do?

Obtaining photographs of severe weather.

4. What do you do with the data you collect?

No data collected yet. The new project—the rooftop mounted weather station— addresses that. It’s a wireless battery-operated magnetic rooftop weather station with GPS, temperature, barometric pressure, humidity, dew point, lightning detection, and wind speed/direction.

There will be a handful of vehicles with weather stations onboard which will often be targeting the same supercells from different vantage points.

The other project is a time-lapse/lightning trigger project I call Vortex, designed to trigger photos with a camera. It runs standalone or over Bluetooth to a smartphone, so that it can be controlled from within the safety of a vehicle to avoid being struck by lightning.

5. Is storm chasing your day job or hobby?

Hobby, although during chase season, it takes a lot of my time.

6. Tell us about the intervalometer you made. How did you utilize the Bantam Tools Desktop PCB Milling Machine in the build?

It uses a Simblee microcontroller to run for years from a CR2032 coin cell. The interface to the device (settings) is provided via an iOS/Android app. The device is opto-isolated and fits on the hotshoe for the camera. It’s designed to be small, power conscious, technically capable, and better than any commercial offerings out there.

Intervalometer/lightning trigger in 3D-printed case on top of the camera.

The lightning detector circuit is designed to only allow near-infrared pulses through (which is where the peak spectrum of lightning can be found), and the reaction time is 183uS from the start of the lightning pulse to the trigger instructing the camera to take a photo. Additionally, because whilst storm chasing, you often want to take time-lapse and lightning shots at the same time, it can take lightning photos in between time-lapse shots. It will detect lightning during the day or night.

I used the Bantam Tools Desktop PCB Milling Machine to rapid prototype the device first. It takes too long to order PCBs in. In this case, I iterated three times to refine the lightning detector sensitivity before ordering final boards from OSHPark.

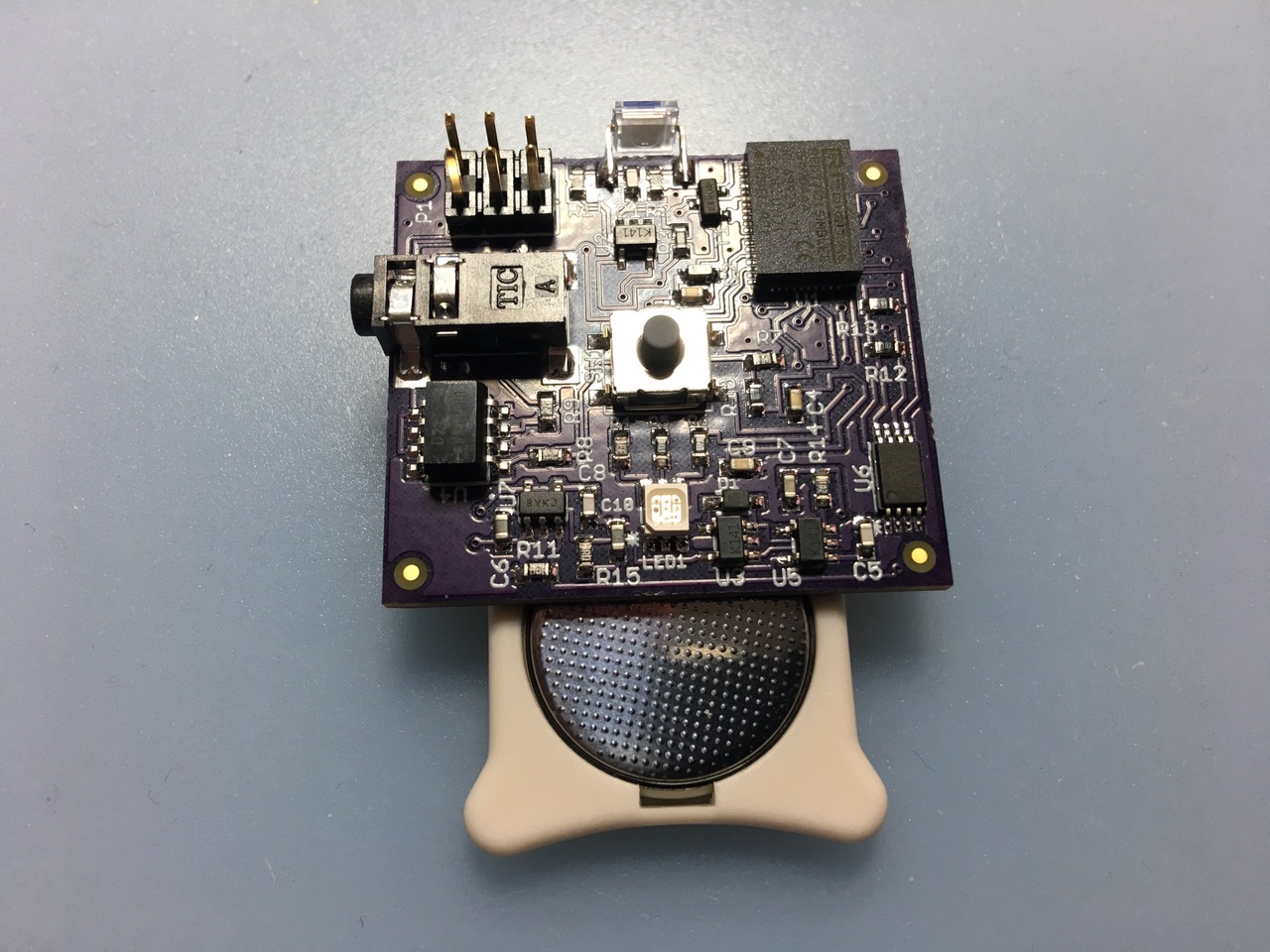

Prototype, with PCB stack during design iteration. Finished board on the right.

7. When and why did you start making your own instruments?

I started making my own instruments to obtain instruments I couldn’t buy.

8. How long have you been using CNC mills?

I’ve been using the Bantam Tools Desktop PCB Milling Machine for 3 years, and prior to that I’ve owned/built 3D printers and laser cutters.

9. What has the Bantam Tools Desktop PCB Milling Machine enabled you to do that you couldn’t before?

Rapid prototype more complex designs for myself and my clients. Breadboarding only gets you so far on larger designs with small pitch ICs.

The board assembly.

10. What’s your favorite thing about the Bantam Tools Desktop PCB Milling Machine?

The software and the precision of the mill.

11. What other projects have you made on it?

A number of prototype commercial products that I can’t go into detail on because of NDAs. I’ve also milled aluminum molds for fishing lures.

12. What projects do you currently have in the works?

The mobile weather station product detailed above.

The finished board.

Fascinating! Thanks so much for sharing, ChasinSpin!

Got a neat project you've made on the Bantam Tools Desktop PCB Milling Machine? We'd love to see it! Tag us on your social media posts or reach out at support@bantamtools.com.