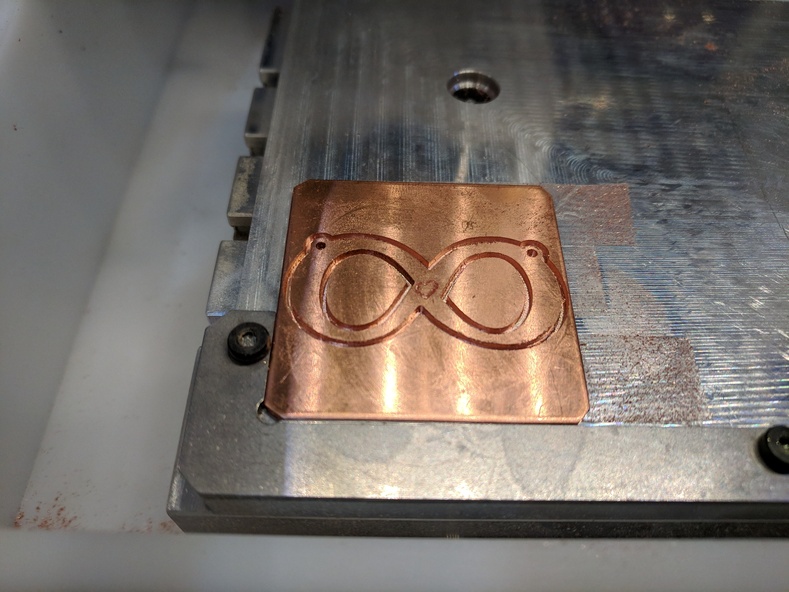

Riley's Copper Love-You-to-Infinity Necklace

A while back, we spotted a gorgeous infinity necklace with matching wooden box that community member Riley Porter had milled on the Bantam Tools Desktop PCB Milling Machine as a gift for his wife. We had to find out more, so we reached out and chatted with Riley, who happens to be owner of Synthetos and co-creator of TinyG, the motion-control system used in our mill. We found out that the necklace itself is made from reclaimed copper, the box top is a beautiful unstained amaranth wood, and the box top inlay is actually made from tinned PCB. Neat!

What was your design process?

I typically use CorelDraw to create the vector images that will in turn be used to create the vector files that I use to import into my CAM program. For toolpaths, I use Aspire to create the CAM by imported the vectors I created in CorelDraw. I also use Aspire to create the non-complex toolpaths, like the circular cutouts and pockets.

How did you choose the materials amaranth wood, PCB, and copper?

The copper was actually from a heat sink that was in a single-board computer that I broke. I was getting ready to toss it, but then I saw the copper part and thought it would be great to use on a project. Since then, I've found good prices on Alibaba for brass and copper plates. The PCB was used as the inlay because the material is easy to mill, and after tinning it, it looks very nice! The amarath wood was used because I had it on hand (for Father's Day, my wife enrolled me in an exotic wood club) and it looked very nice.

Tell us about how you liquid tinned and inlaid the PCB.

The liquid tin I found by trying to figure out how to protect PCBs that I created. It's from MG Chemicals and is pretty nasty stuff. To be very clear, this was just used on the inlay on the top of the wood. I wouldn't use it on anything that was going to have long-term exposure to skin. I'm not a doctor, so I'm not sure if it's an issue, but I wouldn't do it.

What was the most challenging part of the project?

The hardest part of the project was getting the inlay toolpaths right. Typically, you need to shrink the offset of the inlay so that it can fit. I, however, did get lucky, and it just fit the first time around. It was so tight that I didn't have to use any adhesives at all.

What did you learn?

I learned that the Bantam Tools Desktop PCB Milling Machine can cut copper really nicely!

Any tips and tricks you can share?

If you're going to make inlays, make sure you make the inlay a bit smaller (0.02" is the recommended value) than the female inlay.

Also, I used Tung oil for finishing the wood. It's 100% organic and has a great effect. It has an initial odor that I don't mind at all but my wife doesn't like at all, so I suspect this is a personal preference.

How was the gift received?

She liked it very much. She knew I made the box, and she did say that it was cool that the necklace matched the box. What she meant was she thought I had purchased the necklace, so I took that as a compliment.

What else have you made with your Bantam Tools mill?

I've made some breakout boards for circuits I've been playing with that have smaller SMD parts.

What projects do you have on the horizon?

My daughter really liked her mom's necklace, so I think I'm going to make her something for her next birthday. I also have three or four circuits I need to finish. I've been using upverter.com for circuit design and then using the Bantam Tools Desktop Milling Machine Software to mill out the Gerber files.

I'm very happy with the software and have had some really good results with minimal effort. I see that there's an auto-lever feature in the software that's on my radar to test out. I tried milling out some of the copper boards from Alibaba I mentioned earlier with not great results. I think the auto-leveler will help out quite a bit!

Tell us about yourself.

I am a reverse code engineer/malware analyst for a living. I'm one of the creators of TinyG; we write the code that drives the Bantam Tools Desktop PCB Milling Machine. I enjoy making, coding, and hacking.

Thanks so much, Riley! We can't wait to see what else you make on your Bantam Tools Desktop PCB Milling Machine.

We love seeing what our community mills with our reliable little machine. Share your projects with us by tagging your social posts #bantamtools and @bantamtools.