CNC Machining Has Changed the Game for Freedom Electric Supply

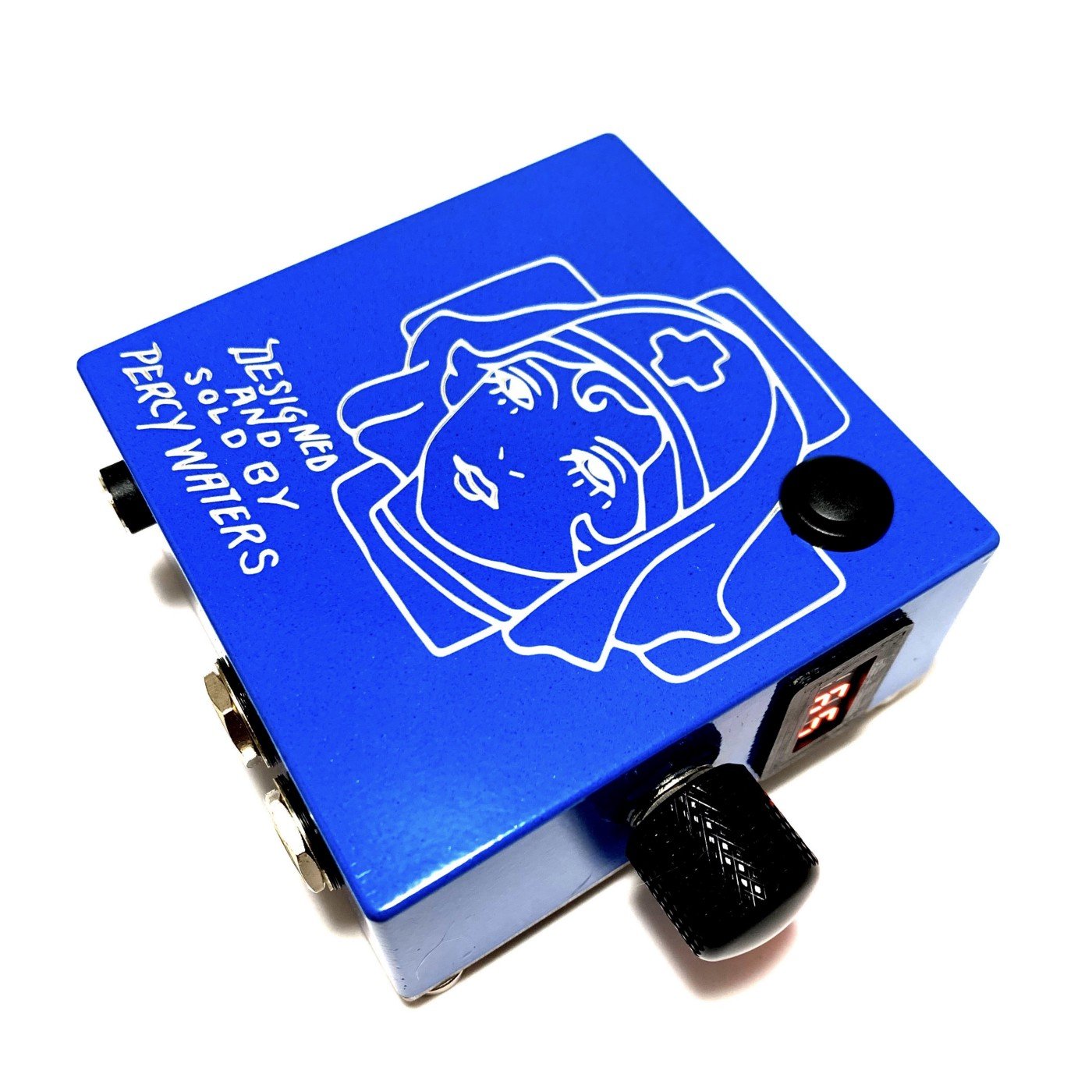

Tattoo artist Ryan Yates is the owner and operator of Freedom Electric Supply in Bozrah, Conn. His small business specializes in making custom, high-quality tattoo equipment for professional artists. Recently, Ryan shared a behind-the-scenes look at his prototyping process on Instagram. We reached out to him to learn more about his experiences with the Desktop PCB Milling Machine. Here’s what he had to say.

1. How did you get into CNC machining? How long have you been using the Desktop PCB Milling Machine?

I’ve been tattooing for over 11 years, but my journey into CNC started back in the early 2000s when I was working in automotive fabrication and tuning. During that time, I learned and honed my machining knowledge and skills, and I have since transferred that skillset over to my career in tattooing. I picked up a Bantam Tools Desktop PCB Milling Machine in January 2020 and I’ve been using it daily ever since. The machine handles a lot of labor involved in my work, and it has freed me up to focus more time on other projects and parts of my business. It’s really allowed me to increase my productivity.

2. Tell us more about your process. Where does the mill fit in?

I use the machine to mill equipment enclosures, knobs, screws, washers, insulators, and other parts. The hardware I make requires the utmost precision. In addition, the mill enables me to engrave custom designs on equipment people order, which adds a nice touch of personality!

3. What has the Desktop PCB Milling Machine allowed you to do that you previously couldn’t?

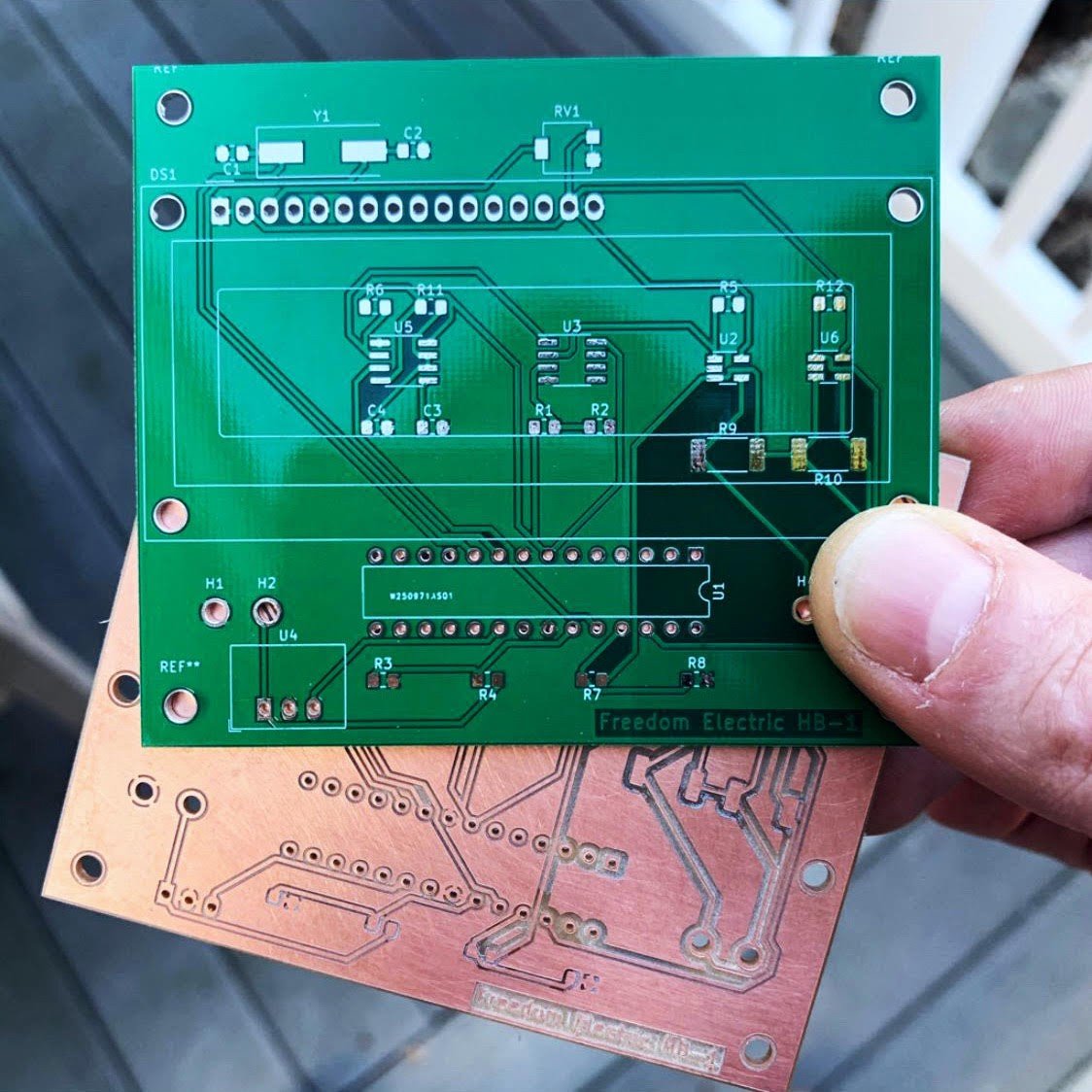

Before I bought the mill, all of my prototypes had to be made by hand. But now, all I have to do is make a quick adjustment in Fusion 360, drop it into the Bantam Tools software, and in a couple of minutes, I have a brand new part. Likewise, I’ve also been able to speed up my circuit board prototyping and production. I used to design the circuit board, send the files off to a production house, and wait for them to send boards back. And I’d often be waiting around just to realize there was something about the board that I needed to fix or could have designed better.

Now, I’m able to design and produce PCBs, fit the components, and test the finished product within an afternoon. Plus, I can make as many changes as I need without having to wait or pay for a production house to make my parts.

4. Are there other kinds of projects you’d like to use the mill for?

As soon as I have time to get back in the garage, I plan on using the Desktop PCB Milling Machine for making automotive parts. I’ve always adhered to the thought that I only buy what I can’t make. It’s very exciting to have that kind of capability in my home workshop.

5. Do you have any tips for those just starting to use the mill or thinking about investing in one for their business?

Just like you guys promise, the mill is easy to set up and start using right out of the box. It’s been able to handle all of the complex jobs I’ve thrown at it. And while some jobs require thinking outside of the box, the resources, tutorials, and libraries found on the Bantam Tools website help guide your process. Before picking up this machine, my ideas were limited by the tools I had available. Now, I’m more imaginative than ever. Being able to rapidly prototype and produce new ideas has completely changed how I make things, and it’s made my job way easier.

About Freedom Electric Supply

Learn more about Freedom Electric on their website and follow Ryan’s journey on Instagram.

Follow Bantam Tools on Instagram, Facebook, Twitter, and be sure to subscribe to the Bantam Tools mailing list to receive more content like this.