Small business owner Curt Hammerly is combining modern CNC machining with traditional pottery strategies to push the limits of ceramics.

Read MoreIn this deep dive, we pull back the curtain on calculating speeds and feeds recipes for your Bantam Tools CNC machine.

Read MoreGo inside Bantam Tools and learn more about the metrology tools we’re using to make precise and reliable desktop CNC machines.

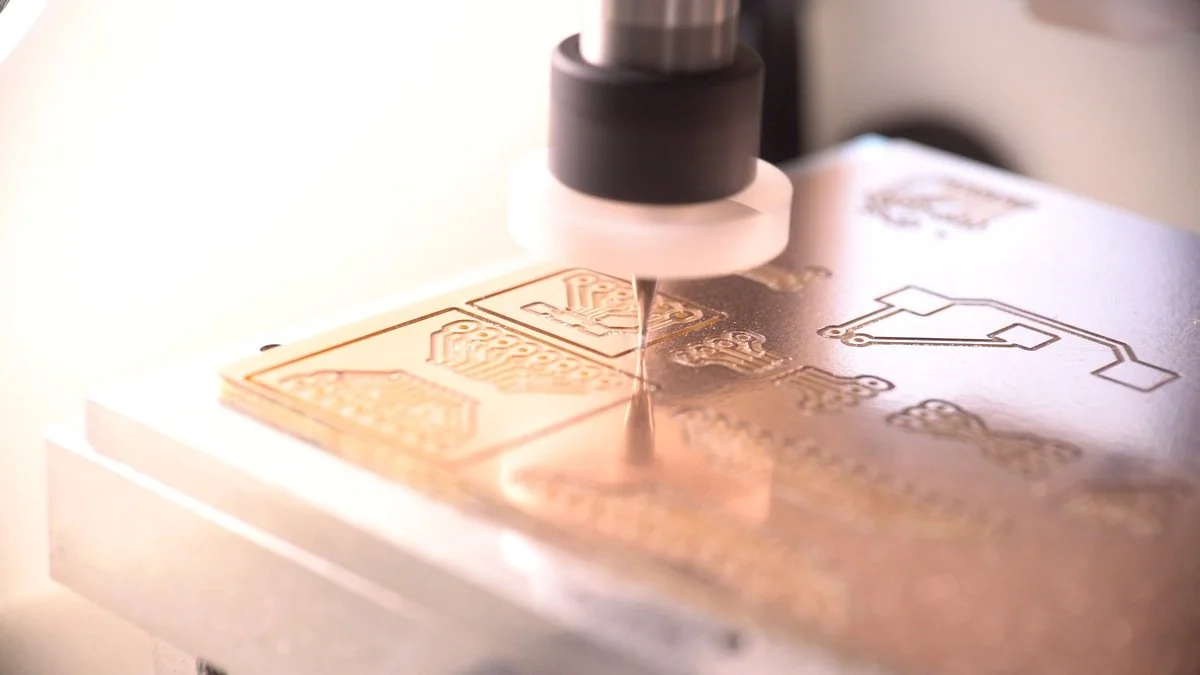

Read MoreLearn how to machine 6 mil traces on your circuit boards using Bantam Tools milling machines.

Read MoreCharlotte Latin School runs a top-notch engineering program and is outfitted with a fully certified fab lab that helps students accelerate their career in STEM and manufacturing.

Read MoreSingle-flute end mills are ideal for high-speed machining operations, making them a go-to for rapid prototyping tools like our Bantam Tools milling machines.

Read MoreHere is a list of components that will wear out over time on your Bantam Tools Desktop CNC Milling Machine.

Read MoreRocket Engineering Company strikes a balance of modern and traditional CNC machining techniques to prototype and fabricate pre-WWII race car parts.

Read MoreGood chip management practices decrease the chances of breaking end mills, issues with your CNC machine, and poor surface finishes.

Read MoreThe Bantam Tools Desktop CNC Milling Machine is now CE compliant and is now shipping internationally.

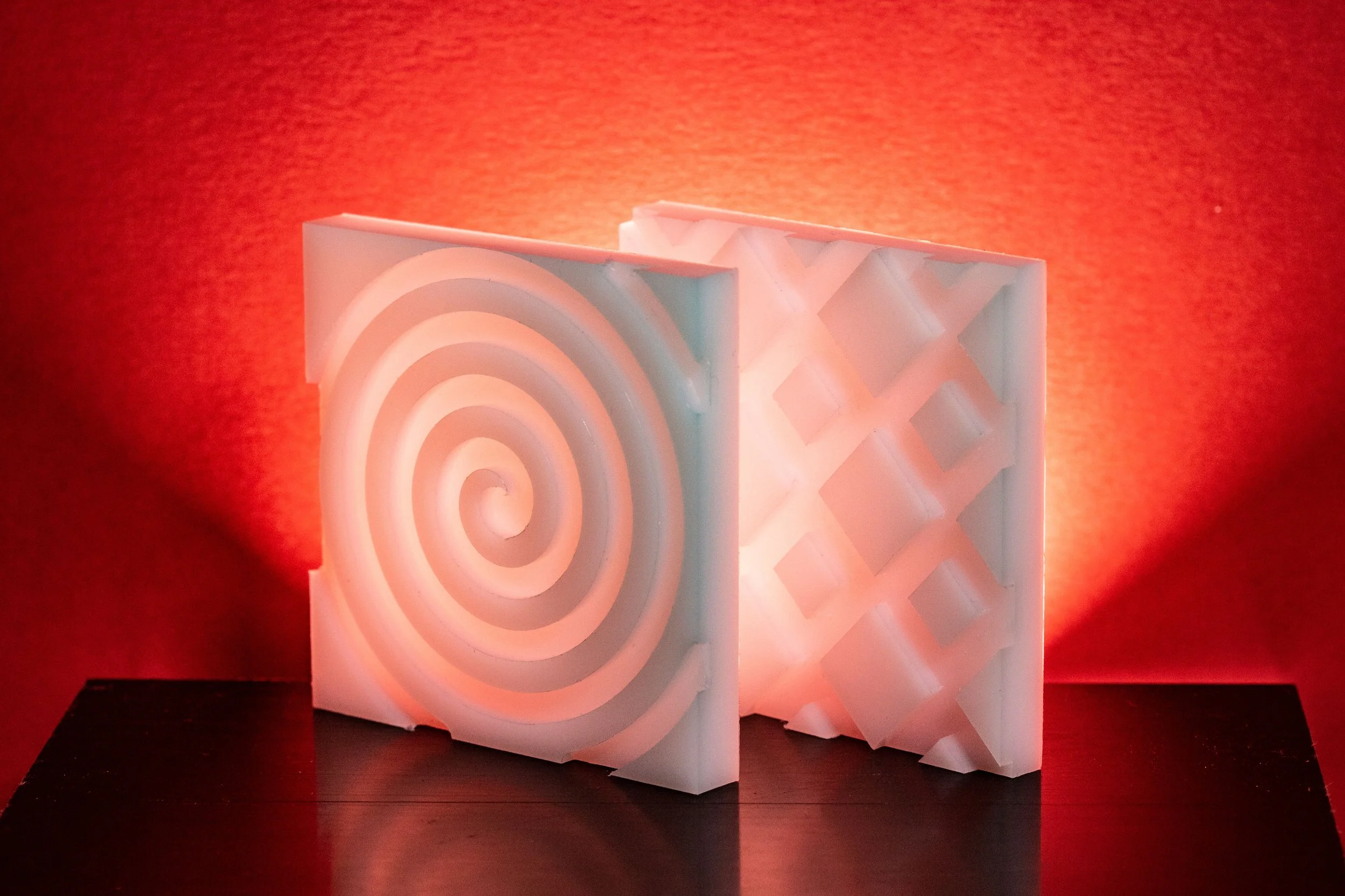

Read MoreKnown for its high strength-to-density ratio, HDPE can easily be machined to produce strong, lightweight parts.

Read MoreOptimizing for chip load improves cut efficiency, the lifespan of your tooling and your machine, and the quality of your parts.

Read More