Material Matters: HDPE

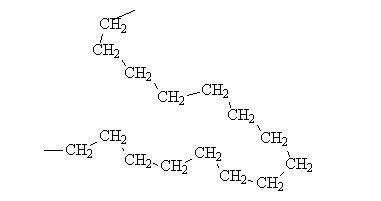

High-density polyethylene (HDPE) is so ubiquitous in our world that it hardly needs introduction. Chances are you have something made of this versatile plastic nearby, whether it’s a drink bottle, mailing envelope, or grocery bag. HDPE is a synthetic polymer made from ethylene. The word polymer comes from the Greek language and literally means “many parts.” Polymers are made up of long chains of molecules and are abundant in nature (such as plant cellulose), but synthetic polymers are made up of much longer chains than natural ones, making them stronger, lighter, and more flexible. The low degree of branching in HDPE’s molecular structure means it can withstand heavier loads. Known for its high strength-to-density ratio, HDPE can easily be machined to produce strong, lightweight parts.

History

In 1869, a firm in New York offered $10,000 to anyone who could make a substitute for ivory. John Wesley Hyatt treated cellulose from cotton fiber with camphor, and the first synthetic polymer was born. Synthetic polymer plastics were touted as the abundant and environmentally safe substitute for natural materials like wood, horn, and shells.

Shortly after, in 1907, the first fully synthetic plastic, Bakelite, was invented by Leo Baekeland. During World War II, plastic production ramped up to make everything from parachutes to body armor and aircraft windows. As the war came to an end, in the late 1940s, demand for oil tanked, and the Phillips Petroleum Company tasked their researchers J. Paul Hogan and Robert L. Banks with finding uses for propylene and ethylene, byproducts of the petroleum refining process.

[Source]

In studying catalysts and how gasses could be converted into gasoline components, Hogan and Banks discovered a new polymer named crystalline polypropylene. The method they developed dramatically reduced the extreme pressure previously required to make polyethylene, and they were able to produce HDPE, which was stronger than anything comparable on the market at the time. Phillips immediately recognized the game-changing potential of HDPE and were in commercial-scale production in less than six years. They first introduced HDPE in 1954 under the brand name Marlex.

Properties

Polymer chain

Versatile

Durable

Nontoxic

Economical

Recyclable

High tensile strength

High strength-to-density ratio

FDA-compliant for food storage

Resistant to chemicals, UV, heat, and moisture

Withstands loads without breaking or cracking

Harder than other plastics and can resist higher pressures

Carbon footprint of production is 5 times lower than aluminum

Specifications

Density: 0.94 g/cm3

Shore hardness: 60 – 70

Tensile strength: 23.0 – 29.5 MPa

Melting point: 267.4°F/130.8°C

Specific heat capacity: 1330 to 2400 J/kg-K

Electrical resistivity: 16 – 18 ohm-cm

Uses

Naturally, when a material is this versatile, durable, and economical, it’s bound to have a wide range of uses. Hogan and Banks' discovery was even designated as a National Historic Chemical Landmark in 1999 by the American Chemical Society because of its importance and prevalence in our daily lives. The list here is by no means exhaustive but gives you an idea of how varied the uses of HDPE are, broken into categories.

Household

Plastic bottles (e.g., detergent, milk, and shampoo)

Grocery bags

Mailing envelopes

Stackable outdoor chairs

Crates

Toys

Food containers

Rope

Construction & Industrial

Tyvek housewrap

Plastic lumber

Geothermal heat transfer piping systems

Corrosion-resistant pipes

Chemical drums

Water infrastructure pipes

Conduit protector for electrical and communications cables

Geotextiles for erosion

Outdoor equipment

Boats

Playground equipment

Basketball backboards

Snowboard park boxes and rails

Other

Medical devices

Fuel tanks

3D printer filament

Auto parts

Syringes

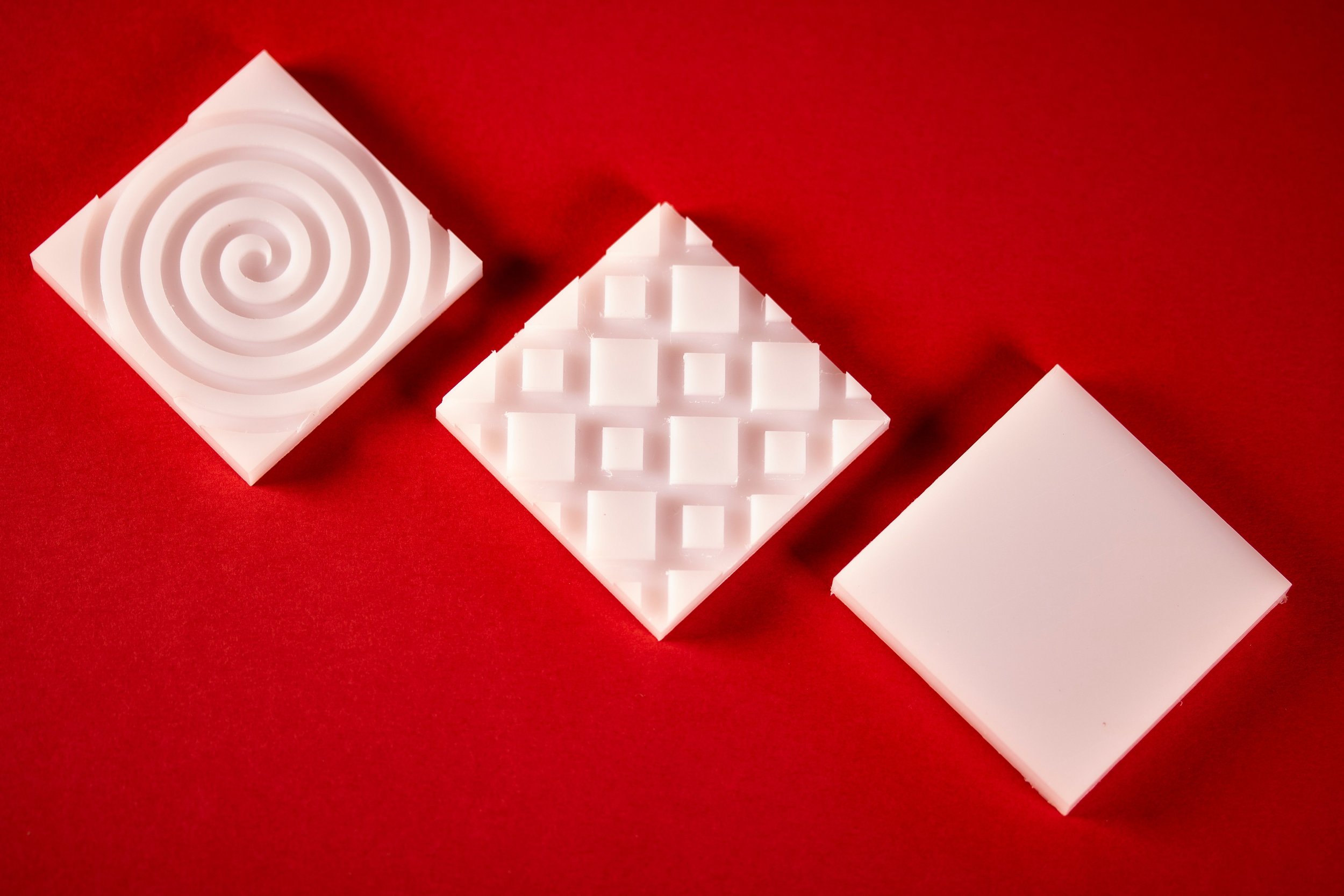

CNC Spotlight

Best bits: In general, larger, single-flute 1/4”, 1/8", and 1/16" end mills are better for HDPE because they cut through material fast and create chips that can handle heat dissipation. For 3D shapes, a 1/4”, 1/8", or 1/16" ball end mill produces the smoothest contours.

Hot tips: Keep a set of end mills specifically for HDPE and other plastics, and never use them to cut metal. For example, we like to use Harvey Tool’s plastic cutters or Datron’s single-flute end mills when doing roughing operations with this engineering plastic. This helps you better manage heat, avoid chip welding, and program high-speed speeds and feeds recipes. On the flip side, for finishing passes we like to use tooling with multiple flutes like the Harvey Tool 1/8” 3-flute flat end mill to get better quality finishes. When using end mills with multiple flutes though, you’ll want to pay close attention to the feed per tooth, so you can rest assured the chips are so small they melt and stick to the tool.

Cool Projects

At Bantam Tools, we build desktop CNC machines with professional reliability and precision to support world changers and skill builders. For the latest Bantam Tools news, sign up for our newsletter. If you’re interested in adding a Bantam Tools machine to your workflow you can order directly from our online store or request a quote.